well Im sure most of you already know Ive been incrementally trying to decrease the amount of engine movement I feel my car has had from day 1.

So my cars manual Ed30 'timeline' of incremental actions Ive researched and subsequently tried has been :

0 miles : car delivered with OE mounts

12,000 miles : ECS Lower Mount Insert review

26,000 miles : VWR 'Fast Road' Engine Mount + Powerflex Insert Bush - Review (Note : this replaces the ECS insert with a complete new mount)

44,900 miles : THS side mounts fitted : this review (Note : VWR Lower Mount + Powerflex bush still remain)

I strongly recommend you take a look at the VWR Lower mount review above as it also outlines lots of general detail about the TFSI engine mounts Im not going to repeat here. (as well as links to RedRobins other engine mount reviews)

For a long time now I have endured a broken oil cap / engine cover due to excessive movement that the dealer refuses to agree is a problem! (Note : I am now out of warranty)

Each time I have made changes the situation has improved to a varying degree, but over time either the new modification has 'softened' and/or the other mounts have continued to deteriorate.

This means unless you do a replacement of all items at once, theres a knock on effect.

I definitely felt that fitting the lower VWR mount hastened the demise of the side mounts (or maybe its just the way the OE mounts age past a certain amount of 'flexibility')

So I got to a point where I could face it no longer, my daughter would have to have a few less toys so that daddy can buy some engine mounts (lol).

The horrendous wheel hop and gradually returned and was painful, so much so I rarely 'pushed on'. As well as that deactivating the cruise control resulted in a jolt as the mounts rocked back and forth, very annoying. I have spent

best part of 6 months driving around the inadequacies of my engine mounts.

Having researched all the choices (see below) , and SteveP kindly setting up a very well timed

THS Engine Mount Group Buy, I jumped at the THS side mounts

(remember I already have a VWR lower mount which is the same as the THS lower version to all extents).

Why THS ?

I believe this represents a good halfway house between OE mounts and fully reworked mountings (BSH/VWR etc)

My previous experience with VWR lower mount showed me just how much a small difference can alter the NVH within the car, combined with stokeballons review on BSH mounts

, and the fact he removed them, prudence was required and I knew some compliance would still be required in the mounting system.

I like the concept of taking the OE design and improving it as well. (Although longer term this may also mean the mounts 'age' just like OE, but VWR/BSH mounts may not)

And lastly the price point is appealing, especially as theres a chance I dont like them!

Sourcing

from

THS Performance

"2005-Present (MK5/6 Platform VAG cars)

THS Performance have developed a new engine mounting system for the 1.8T FSI and 2.0T FSI MK5 and MK6 type application.

The outer casing of the mounting system maintains stock appearance, whilst the internal rubber has been carefully re-engineered by means of shape and stiffness to reduce engine/drive train movement. The rubber is 30% stiffer than standard but becasue of the re-engineered shape the engine movement is reduced by over 50% without transmitting any serious engine vibration back into the vehicle unlike polyurethane mounts.

The extra control over the engine and drive train makes for a much more precise power transmission to the road both on 2wd and 4wd applications.

Significantly reducing wheel hop on 2wd cars. Other benefits are reduced stress on the exhaust system."

cost was £160 (£200 normally) via the forums group buy.

Fitting

It looks scary but in reality its not that bad, as long as you take your time and have the right tools.

I was quoted by Awesome GTi Manchester around 1.5 to 2 hours labour (£82.50 to £110), but decided to attempt it myself.

SteveP quotes around an hour, it took me around 2.

(install guide copied from SteveP's notes)

Tools Needs: -

19 (maybe 18 mm lol), 13 & 10mm Sockets

16mm deep Socket

Couple of medium and long extension bars

T20 Torx Screwdriver

Jack and a wooden block to support the engine

Also found a magnetic pick up tool very helpful :grin:

On the drivers side mount I removed the bolts/screws for the washer filler neck, charcoal cannister and expansion tank, then unbolted the side support bracket.

Then you can get at the mount, that's unbolted by removing the2 x 16mm bolts and 2 x 19mm bolts.

Pics of the driver side mount: -

This side done: -

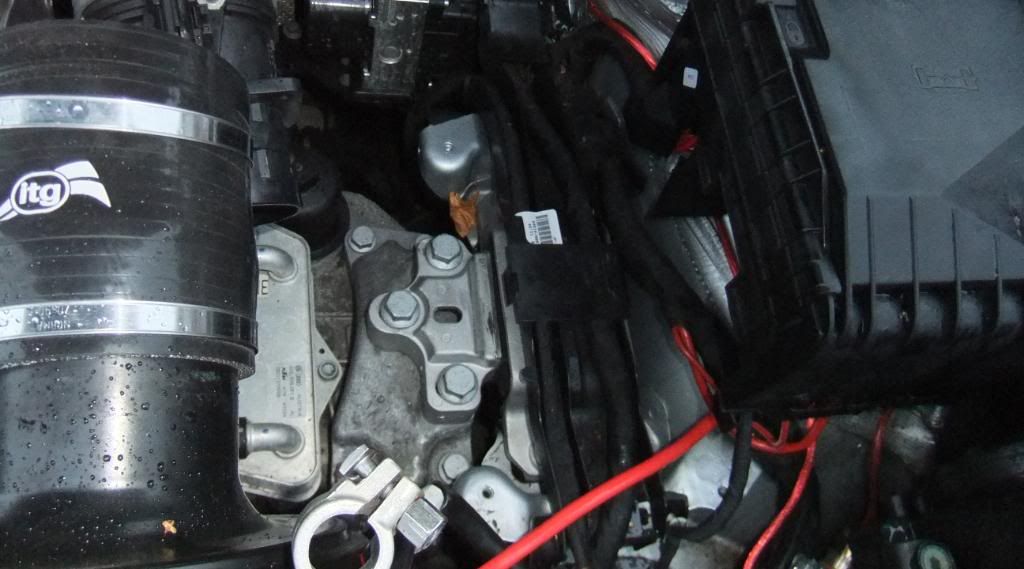

For the passenger side mount, the battery and battery tray (3 x 13mm bolts) need to be removed, then unclip the wiring loom tray the rest on top of the mount.

Then unbolt the three 19mm bolts on the engine side of the mount and the 4 x 19mm.

Pics of the Passenger side: -

This side done

my comments

I reused my original bolts

Use a torque wrench! +1/4 turn is a lot.

keep bolts in removal position order by punching holes in boxes new mounts come in to store bolts

fit bolts to chassis side first THEN engine side, if it feels wrong dont force or risk a cross thread!

use a jack to support the engine (THIS IS A MUST), once you see how much it all moves with a mount removed youll wonder why the OE mounts arent twice the size they are.

If you have a map e.g. REVO theres a chance the settings may get lost so have an SPS switch handy

other data

comments as fitted by Gaz

original mounts query thread by me

torque specs

Bolt numbers and approximate costs should you wish to buy replacements

Engine Mount =

2 x N 019 502 13 - M8x25 (£0.51 each)

1 x N 905 969 06 - M10x55x32 (£4.11 each)

2 x N 105 524 02 - M12x1,5x70 (£2.35 each)

1 x N 910 296 02 - AM10x55/M6x12 (£3.94 each)

Gearbox Mount =

4 x N 905 969 06 - M10x55x32 (£4.11 each)

2 x N 105 524 02 - M12x1,5x70 (£2.35 each)

Lower Mount =

1 x N 911 671 01 - M10x75 (£1.65 each)

1 x N 910 661 01 - M10x35 (£1.65 each)

All prices are inc VAT and as a guide only (part list from ETKA for a 2008 Golf).

TODO : describe old mounts

TODO : add pic of old mounts

Alternative engine mounts to consider

Theres a considerable amount of choice out there for engine mount replacements, its just a question of how far you want to go, and how much NVH you are willing to put up with.

BSH mounts

(non OE appearance but stealth like , poly bushing , inc new bolts) 78a durometer bushings

BSH speedshop

stokeballons review

vortex review

golfmkv review

VWR mounts

(non OE appearance, poly bushing)

VWR Racing

RR's lower mount review

my review of lower mount

RR's full set review

VF Engineering

(look the same as BSH version)

VF Engineering

BlackForestIndustries (US)

BlackForestIndustries

supply inserts (passengers side) , preassembled or full items (drivers side) , 3 levels of hardness from 1 to 3

"Stage1 65a poly inserts vs. the stock (45a)inserts are 50% stiffer than stack. Will increase some vibration in cabin - especially during certain rpm ranges"

they have a useful diagram of the collapsed OE mount .....

Use OE new mounts and fill as per TeutonicTamer

TT's thread on modded engine mounts

My only concern is that its still 2 different types of material that may seperate and age differently. Not entirely convinced it will last for very long.

I remember jonnyc also filled some engine mounts for his S3

Specific noise data

Im trying to compare to how I previously reported when the VWR lower was fitted. Now bear in mind that this got quieter over time as both it and other mounts have softened further

idle or idle+aircon

in a previous review I complained that a vibration was existent with air con on once the VWR lower had been fitted, ironically with the 2 side mounts fitted AND new REVO software this is now gone! something has meant the harmonics have changed out of this range. At idle my car is now quieter than it was before.

clutch biting point

I always have moaned that the DMFlywheel and clutch on the GTI is pants. feel is non existent. Immediately after fitting I felt the noise at the biting point was worse, but almost straight away this went, now the

noise at takeup has gone as feels much less harsh (ironic when you consider the NVH increases in all other phases, I would theorise the mounts 'settled' post installation, or maybe Im just deaf from the Grr...)

acceleration mild : feels coarse/harsh, +50% NVH increase. level increases as revs rise

deceleration : feels coarse/harsh, +50% NVH increase. level increases as revs rise

acceleration full : wtf! way more noise, easily +100% or more, when I spoke to Gaz I mentioned its more like an old mk2escort on twin 45DCOE carbs at full chat!

its intake/gearbox + just about any noise you can think of lol. Sounds like I have an intake fitted when I dont.not for the faint hearted or the paranoid.

You can modulate some of the sound with load applied but some still remains even on a flat throttle.

however cruising at 70-80mph is almost identical to before. Definitely lower speeds you notice the noises more.

now that sounds bad but it isnt really. I have now completed over 200 miles and already the noises are improving.

But in reality the car is no longer the paragon of smoothness you hoped for, but for me the benefits FAR outweigh the disadvantages of fitting.

I find it hard to imagine what the full BSH/VWR mounts sound like, if this is the halfway house.

Plus Points

OE look. OE design but better.

Fits just like OE

Warranty friendly

Its an easy to fit modification that looks daunting but isnt (but could be if you get it wrong)

Depending on how they last, I would say good value.

Engine no longer moves at all. Engine Cover/Oil Filler cap are now safe (as are aftermarket intakes if you have one installed re: forge snapping bracket)

Aural improvement if thats your thing. Grrrrr TM according to RedRobin

adds some intake like type noise even with stock engine cover

wheelhop is gone (finally)

clutch bitepoint noise has improved significantly.

THS Performance support seems to so far have been top notch with questions answered quickly and even torque settings supplied.

Minus Points

NVH. not really in keeping with the GTI fast but refined ethos. coming from very worn OE mounts they are a vast difference.

Long term resilience as yet unproven.

May impact if you planned to sell the car, prospective buyer will just compare to OE sounds and reckon your gearbox/engine is fkd

The lower mount (which I didnt fit , as I have a VWR one) is much less of a DIY proposition.

Summary

Until someone creates adaptive engine mounts that can be retrofitted to mk5/mk6 golfs the whole area is a compromise of

reduced engine movement VS Noise/Vibration/Harshness levels.

These can be effected by design and nature of the components used to build the engine mounts (contact surface area ,durometer of rubber/poly used etc)

The OE mount does a fantastic job at keeping noise levels low but allows significant engine movement even when new (and gets % wise far worse as they wear more).

I guess if you could get them cheap enough, replacing the OE mounts with new OE mounts every 5-10k miles could be an option but thats not for me, besides even when new they arent that great.

So if like me you can sacrifice some comfort for a fully restrained engine you will have to fit aftermarket mounts using one of the options I listed above.

My advice after doing this incrementally (assuming you place engine restraint over noise levels) would be to

IDEAL SCENARIO : fit all 3 mounts (2 x side + lower) at the same time so that the loads are spread evenly across all stress points.

Doing it incrementally I believe, has greatly shortened the life of my OE side mounts as well as my newer lower mount. all at once or nothing.

COMPROMISE SCENARIO 1 :

less effective (but more cost efficient) maybe to consider 2 x side with the dogbone insert, that way you can fit it all at home without the need for a press.

(I do however feel this is suboptimal and may not last as long as in combination with a 'good' lower mount), I havent tried it but the noise levels maybe reduced too.

COMPROMISE SCENARIO 2 :

fit lower VWR/THS mount and 2 new OE mounts, and replace the OE mounts frequently. that way noise is significantly reduced, OE mounts arent left to age to any great extent.

Its a double edged sword as you want them to hold the engine tight but at the same time soften to reduce noise levels.

At this stage 200 miles since fitting, I am very happy with the THS side mounts and Im quite happy to give them 1000 miles or more to bed in. :happy2:

Ill be sure to update this review as the miles progress........

thanks to everyone for their help and input on all aspects of providing data etc of this review. :happy2:

No comments:

Post a Comment